|

1/32nd

scale

Focke-Wulf Fw-190D-9 |

|

Page

Two

|

|

|

|

|

|

|

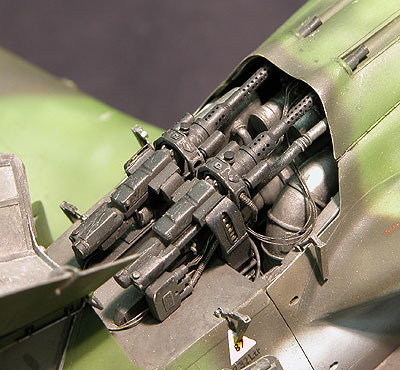

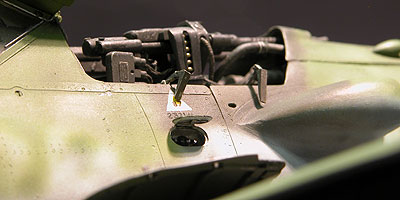

MG131 COWL GUNS The vacuum-formed styrene cowl gun cover is hinged and opens to reveal the two MG 131 13mm machine guns. Latches are fully functional and made from brass and styrene. Like the engine doors, the numbers on the inside of the cover are handpainted and the metal finish is Rub'nBuff, graphite, and various mixtures of paint. Gun barrels are turned brass and include .001 inch thick perforated barrel jackets. Simulating the rounds of 13 mm ammunition are individual pieces of turned brass that fit inside the .0025 inch thick sheet plastic feeds. The rest of the gun and gun mount parts are made from hand shaped and lathe turned pieces of styrene with various details in copper wire and stretched sprue. Octane triangles above the hinged fuel door was airbrushed. The octane and capacity numbers are a combination of decals and hand painting. |

|

|

|

|

|

|

MG151/20 WING GUNS The wing gun doors are hinged to expose MG 151 20 mm cannons and cannon bays. The doors were vacuum-formed and have six latches each. The barrels are turned brass with all other parts hand shaped or lathe turned styrene and ABS. Again, stretched sprue and copper wire was also used. Lettering is hand painted. |

|

|

|

|

|

|

|

|

COCKPIT Except for extensively modified and detailed Waldron rudder pedals the cockpit is completely scratchbuilt. The Waldron pedals were cut in half, reshaped and put back together. The reworked pedals are mounted on movable brass frames with lathe turned toe brake cylinders and mechanical linkages. The rudder pedals (push one in and the other moves out), control stick and throttle are movable. Clear plastic covered instrument dials are hand painted with the attitude indicator a turned plastic sphere. Instrument bezels are styrene. The windshield frame is styrene and the "glass" is clear butyrate. The sliding canopy is made of three sets of vacuum-formed parts -- the inner frames, the clear glazing, and the outer frames. The canopy handwheel and external drive screw turn via rack-and-pinion gears as the canopy is moved. The combined armor plate and headrest is attached to the canopy by operating pivots to compensate for the narrowing width of canopy track as the canopy moves aft. The slack in the antenna wire is taken up by a simple pulley system. All operating parts function as on the actual aircraft. Artist's note: I chose to model an aircraft with a flat-sided hood since I wanted to make the antenna wire pulley system work. I also didn't want to paint the cockpit RLM 66 Black Grey. The RLM called for cockpits of Luftwaffe fighters to be RLM 66 in mid-1944. I rationalized a few early D-9s might have had RLM 02 cockpits, so the cockpit on this D-9 is RLM 02. Current information seems to show that D-9 flat-sided canopies did not have the pulley feature...I should have built an A-8. Two years into the project I found a material suitable for the antenna wire. At a local model club swap meet was a 1/48th Aurora D-VII. Always interested in Aurora plastic (and Jo Kotula artwork), I decided to take a look. Inside was a small spool of flexible black plastic intended for rigging. Over twenty years old at the time, it was still completely flexible. It was the right thickness for 1/32nd scale antenna wire and soft enough to take the turn of a scale pulley without forming any kinks. Out of nowhere, the problem was solved. |

|

|

|

|

FUSELAGE INTERIOR AND DOORS The left side fuselage door is hinged to expose the methanol-water tank, ribs, stringers, control cables and other interior details. The door has four latches. The footstep is retractable and the kickplate and the handhold are both spring-loaded with an HO freight truck spring. The antennas were built from steel wire, stretched sprue, and sheet plastic. The raised strips on the side of the fuselage and the wing fillet are .0025 inch thick plastic sheet. The radio compartment door on the right side of the fuselage is hinged to expose the radio and interior details including fuel lines and control cables. The door has three latches. The first aid door is removable as are the methanol-water filler doors. MW 50 doors are attached by a fine wire and fuel doors are hinged. |

|

|